FerrumFortis

Trade Turbulence Triggers Acerinox’s Unexpected Earnings Engulfment

Friday, July 25, 2025

Molten Metal Metamorphosis: MIT's Magnificent MOE Marvel

Dr. Donald Sadoway's laboratory at MIT pioneered the discovery of Molten Oxide Electrolysis in the 1980s, initially developing the technology for NASA's lunar mission to extract oxygen from moon rocks using electrolytic cells, though the process was deemed unviable for terrestrial applications due to the requirement for exotic electrode materials that were non-existent on Earth. However, Sadoway's continued research breakthrough came when his team found innovative ways to adapt the process using readily available materials like aluminum and copper electrodes, making the technology commercially feasible. This revolutionary advancement led to the 2012 founding of Boston Metal, an MIT spinoff company that commercialized Sadoway's proprietary MOE technology to revolutionize steel production by using electricity to create steel with zero carbon emissions, replacing traditional carbon-intensive blast furnace methods. The company's modular MOE cells, each the size of a school bus, now process iron ore through an electrochemical process that passes electricity through iron oxide mixed with specialized compounds, representing a tonnage metals platform technology that could potentially cut 5% of global CO2 emissions from the steel industry.

Key Technical Process:

- Input: Iron ore (iron oxide) fed into modular MOE cells

- Process: Electricity passes through iron oxide mixed with specialized electrolyte compounds

- Electrodes: Aluminum and copper electrodes (breakthrough from original exotic materials)

- Output: Pure steel with oxygen as byproduct, zero carbon emissions

- Scale: Industrial-sized cells comparable to school bus dimensions

Total Funding Summary

2019 | Series A | $20M | Breakthrough Energy Ventures, Prelude Ventures, OGCI Climate Investments, The Engine

2021 | Series B | $50M | Piva Capital (lead), BHP Ventures, Devonshire Investors/Fidelity, existing investors participated

2023 | Series C | $120M | Details from January 2023 round

2023 | Series C (continued) | $262M | Total Series C amount by September 2023

2024 | Series C2 | $20M | Additional funding round

2025 | Convertible Note | $51M | Recent convertible note investment

Total Funding Estimates: - $469M, 14 rounds from 22 investors

Revolutionary Reactor Realization: Reinventing Rusty Routines

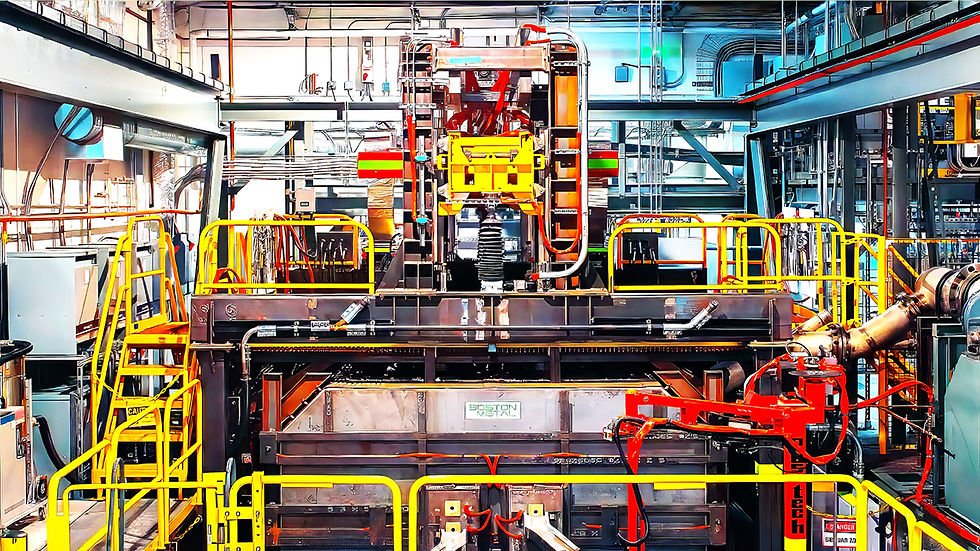

Boston Metal's groundbreaking achievement in commissioning their multi-inert anode Molten Oxide Electrolysis industrial cell represents a paradigmatic shift in metallurgical manufacturing, demonstrating that clean steel production at commercial scale is not merely theoretical but tangible reality. The Massachusetts facility successfully produced over one metric ton of high-quality molten steel through an electrochemical process that eliminates carbon dioxide emissions entirely, requiring only renewable electricity to transform iron ore into liquid metal at temperatures exceeding 1600°C. CEO Tadeu Carneiro emphasized the significance, stating, "I can now say that tonnage steel is flowing from our multi-inert anode MOE cell. With this milestone, we are taking a major step forward in making green steel a reality & we're doing it right here in the U.S., demonstrating a critical innovation that can enhance domestic manufacturing." The reactor's successful operation validates years of research & development, proving that electrochemical steelmaking can replace traditional blast furnace technology while maintaining product quality standards demanded by industrial applications. This technological breakthrough positions Boston Metal as a frontrunner in the global race to decarbonize steel production, addressing one of the most challenging industrial emission sources

Electrochemical Excellence: Eliminating Emissions Entirely

The Molten Oxide Electrolysis process fundamentally reimagines steelmaking by leveraging electrochemistry to split iron oxide bonds directly, releasing only oxygen gas as a byproduct while producing pure liquid metal suitable for immediate processing. Unlike conventional steelmaking that requires multiple carbon-intensive steps including coke production, ore sintering, blast furnace reduction & basic oxygen furnace refinement, MOE accomplishes the same result in a single, efficient operation powered entirely by electricity. Chief Scientist Guillaume Lambotte noted, "This achievement is the sum of all the contributions from every member of our exceptional team. We have been pushing the boundaries of electrochemistry, materials science & engineering to scale-up Molten Oxide Electrolysis." The process operates by immersing inert anodes in an electrolyte containing iron ore, with electrical current splitting molecular bonds to separate pure metal from oxygen at extreme temperatures. This revolutionary approach eliminates the need for hydrogen infrastructure, carbon capture systems, or process water, dramatically simplifying industrial operations while achieving zero-emission production. The high-purity molten metal produced can be sent directly to ladle metallurgy, streamlining downstream processing & reducing overall production complexity compared to traditional methods

Financial Fortification: Funding Future Fabrication

Boston Metal's successful $51 million convertible note investment from prestigious investors including BHP Ventures, Breakthrough Energy Ventures, Piva Capital & SiteGround demonstrates sustained confidence in the company's dual-business strategy & technological capabilities. The funding arrives strategically following the industrial cell commissioning success, providing capital to accelerate both critical metals operations in Brazil & continued green steel development initiatives. Laurel Buckner, VP of Ventures at BHP, stated, "Boston Metal's unique process makes steel production efficient, cost-effective & more sustainable. The investment in Boston Metal continues to drive BHP Ventures' support of game-changing technologies that drive innovation for the broader industry." The convertible note structure allows investors to participate in future equity rounds while providing immediate capital for scaling operations, particularly the second phase of Boston Metal's Minas Gerais facility scheduled for mid-2026 deployment. This financial backing enables the company to capitalize on recent technological milestones while maintaining development momentum toward commercial steel production. The investment validates Boston Metal's market positioning & technological differentiation in the competitive clean technology landscape, providing resources necessary for achieving industrial-scale deployment

Brazilian Breakthrough: Building Business Beyond Boundaries

Boston Metal's strategic expansion into Brazil through their Minas Gerais critical metals facility represents a pragmatic approach to commercializing Molten Oxide Electrolysis technology while generating immediate revenue streams from high-value materials recovery. The facility utilizes MOE to extract niobium, tantalum & tin from mining waste, transforming previously discarded materials into profitable commodities while advancing circular economy principles. This proven application of MOE technology demonstrates commercial viability & provides cash flow to support continued green steel development, creating a sustainable business model that doesn't rely solely on future steel market transformation. The Brazilian operation is expected to begin generating revenue in 2025, with the second phase expansion funded by recent investment proceeds scheduled for mid-2026 completion. This dual-market approach allows Boston Metal to establish manufacturing expertise & operational capabilities while building customer relationships in the metals industry. The critical metals business also provides valuable operational data & process optimization insights that directly benefit green steel development efforts, creating synergistic benefits across both business units. The Brazilian facility's success validates MOE technology's versatility & commercial applicability beyond traditional steelmaking applications

Strategic Stewardship: Strengthening Senior Supervision

The appointment of Eduardo Bartolomeo, former CEO of Vale & globally respected metals executive, to Boston Metal's Board of Directors significantly strengthens the company's leadership capabilities as it transitions from technology development to commercial deployment. Bartolomeo's extensive experience in global metals markets, large-scale operations & strategic business development provides invaluable guidance for navigating the complex challenges of industrial-scale manufacturing & international market expansion. His leadership during Vale's transformation into a global mining leader offers directly applicable insights for Boston Metal's growth strategy, particularly regarding operational excellence, safety standards & stakeholder management in heavy industrial environments. The board appointment signals Boston Metal's commitment to assembling world-class leadership capable of executing ambitious commercialization plans while maintaining technological innovation momentum. Bartolomeo's industry relationships & market knowledge create strategic advantages for customer development, partnership formation & supply chain optimization as Boston Metal scales operations. His involvement also enhances credibility with potential customers, investors & regulatory authorities, facilitating market acceptance of revolutionary steelmaking technology. The leadership reinforcement demonstrates Boston Metal's maturation from startup to industrial company capable of delivering transformative impact on global steel production

Demonstration Deployment: Designing Decarbonization Destiny

Boston Metal's planned demonstration plant for steel production by 2028 represents the critical bridge between laboratory success & commercial-scale deployment, requiring careful site selection & engineering optimization to validate full-scale manufacturing capabilities. The demonstration facility will prove MOE technology's ability to produce steel at volumes sufficient for industrial customers while maintaining cost competitiveness with traditional blast furnace operations. Senior Vice President Adam Rauwerdin emphasized the company's commitment to proving technology viability, noting that emissions from their current facility are so clean they can be vented into parking lots shared with daycare centers. The demonstration plant will serve as a showcase for potential customers, investors & regulatory authorities, providing tangible evidence of green steel production capabilities at meaningful scale. Site selection considerations include access to renewable electricity, proximity to iron ore supplies, transportation infrastructure & regulatory environments supportive of innovative manufacturing technologies. The facility will also serve as a training ground for operational personnel & a testing platform for process improvements before full commercial deployment. This strategic approach minimizes technical & commercial risks while building confidence among stakeholders regarding MOE technology's industrial readiness

Market Metamorphosis: Materializing Massive Momentum

The global steel industry's urgent need for decarbonization creates unprecedented opportunities for Boston Metal's revolutionary technology, particularly as environmental regulations tighten & carbon pricing mechanisms expand worldwide. Traditional steelmaking contributes approximately 10% of global carbon emissions, producing over 3 billion metric tons of CO₂ annually from 2 billion metric tons of steel production, creating enormous pressure for cleaner alternatives. Boston Metal's MOE technology addresses this challenge by eliminating carbon from the steelmaking equation entirely, using renewable electricity to achieve the same metallurgical results without fossil fuel combustion or carbon-intensive reduction processes. The company's technology offers particular advantages in regions with abundant renewable energy resources, where electricity costs continue declining while carbon pricing mechanisms increase traditional steelmaking expenses. Industrial customers increasingly prioritize supply chain decarbonization to meet sustainability commitments & regulatory requirements, creating demand for verified low-carbon steel products. The technology's ability to process all iron ore grades provides operational flexibility unavailable to traditional blast furnaces, potentially reducing raw material costs while improving product quality. Market acceptance will depend on demonstrating cost competitiveness & reliable supply capabilities at commercial scale

Technological Triumph: Transcending Traditional Techniques

Boston Metal's Molten Oxide Electrolysis represents a fundamental reimagining of metallurgical processes, replacing centuries-old blast furnace technology with electrochemical precision that delivers superior results while eliminating environmental impact. The inert anode technology enables scalable production by preventing electrode degradation that previously limited electrochemical metal production, solving a critical technical challenge that blocked commercial deployment. The process achieves remarkable efficiency by directly converting iron ore into liquid metal without intermediate steps, eliminating energy losses associated with multiple heating & cooling cycles in traditional steelmaking. Temperature control at 1600°C ensures optimal metal quality while the electrochemical environment prevents contamination from combustion byproducts that can affect steel properties in conventional processes. The technology's modular design allows flexible scaling from laboratory demonstrations to industrial production, with individual cells operating independently to provide operational redundancy & maintenance flexibility. Process automation reduces labor requirements while improving safety by eliminating exposure to combustion gases, molten coke & other hazardous materials associated with blast furnace operations. The clean operation environment enables steel production in urban locations previously unsuitable for heavy industry, potentially revolutionizing manufacturing geography & supply chain logistics

Key Takeaways

• Boston Metal successfully commissioned its first industrial-scale Molten Oxide Electrolysis cell in March 2025, producing over one metric ton of clean steel without carbon emissions through revolutionary electrochemical processes

• The company secured $51 million in convertible note funding from strategic investors including BHP Ventures to accelerate critical metals operations in Brazil & advance green steel commercialization toward 2028 demonstration plant deployment

• MOE technology eliminates traditional steelmaking's carbon-intensive processes by using renewable electricity to convert iron ore directly into high-quality molten metal, potentially cutting 10% of global carbon emissions from steel production

Boston Metal's Metallurgical Metamorphosis: Molten Marvel

By:

Nishith

Sunday, August 3, 2025

Synopsis:

Based on company releases & industry reports, Massachusetts-based Boston Metal achieved a transformative milestone in March 2025 by successfully commissioning its first industrial-scale Molten Oxide Electrolysis cell, producing over one metric ton of clean steel without carbon emissions. The breakthrough validates the scalability of their revolutionary electrochemical process that uses renewable electricity instead of coal to convert iron ore directly into high-quality molten metal at 1600°C. Following this technical achievement, Boston Metal secured $51 million in convertible note funding from strategic investors including BHP Ventures & Breakthrough Energy Ventures to accelerate commercialization. The company's dual-business strategy targets both immediate revenue generation through critical metals recovery in Brazil starting 2025 & long-term steel decarbonization through demonstration plant construction by 2028.